Precision, Quality, and Consistency in Every Part

Quality

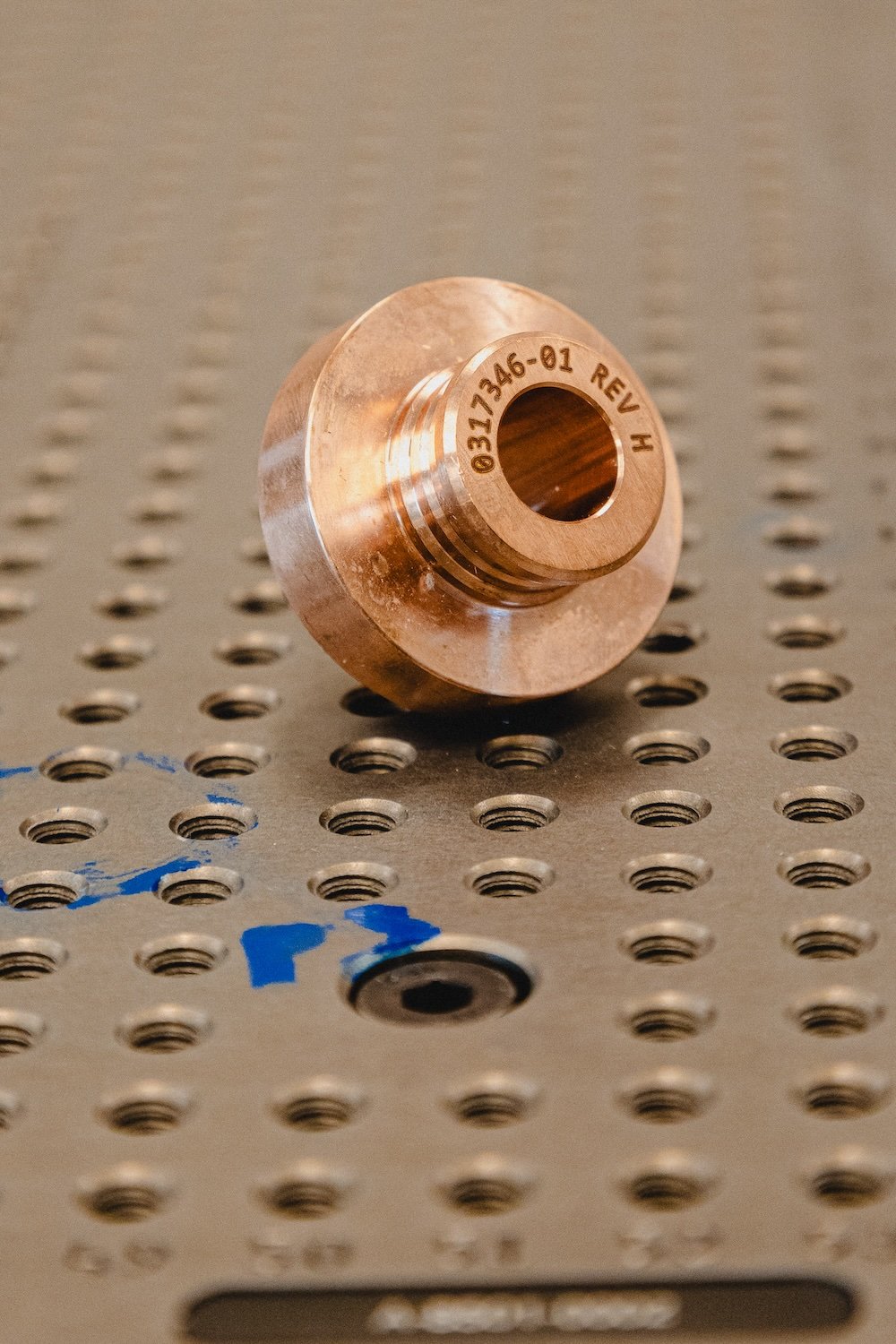

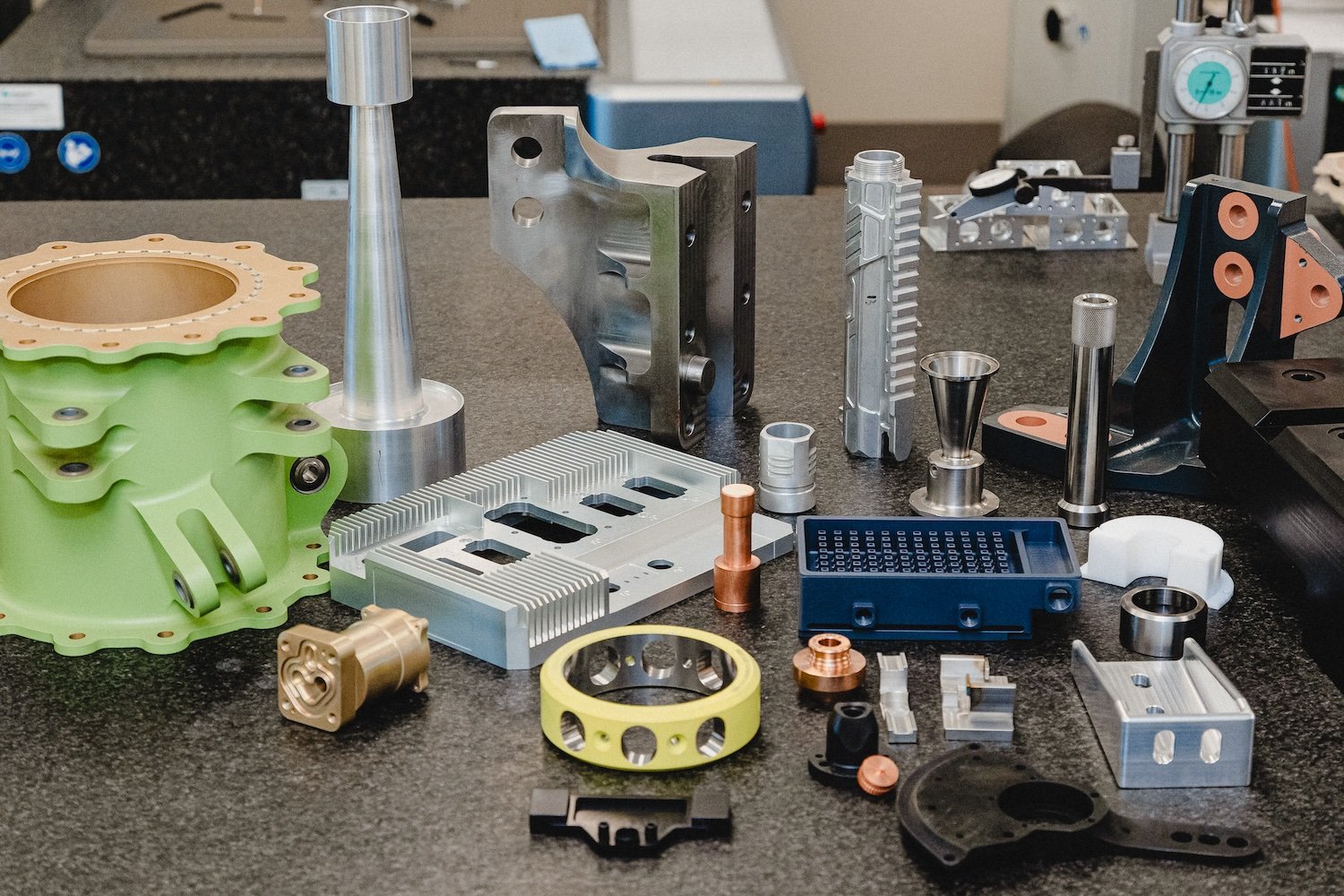

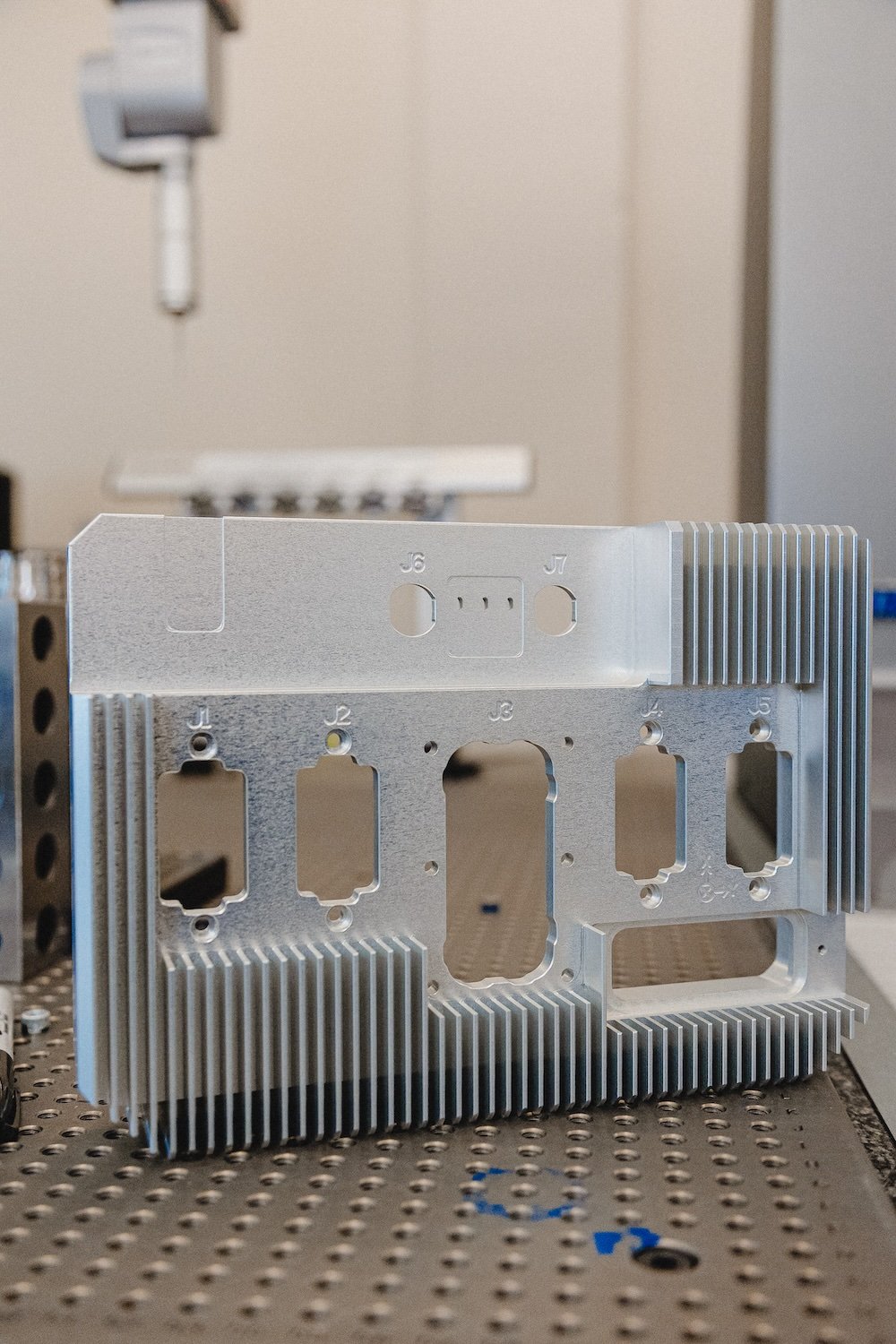

At TORQ Manufacturing, quality isn’t just a promise—it’s a practice embedded in every part of our process. With AS9100D certification, we adhere to stringent aerospace industry standards, ensuring each component meets rigorous quality requirements.

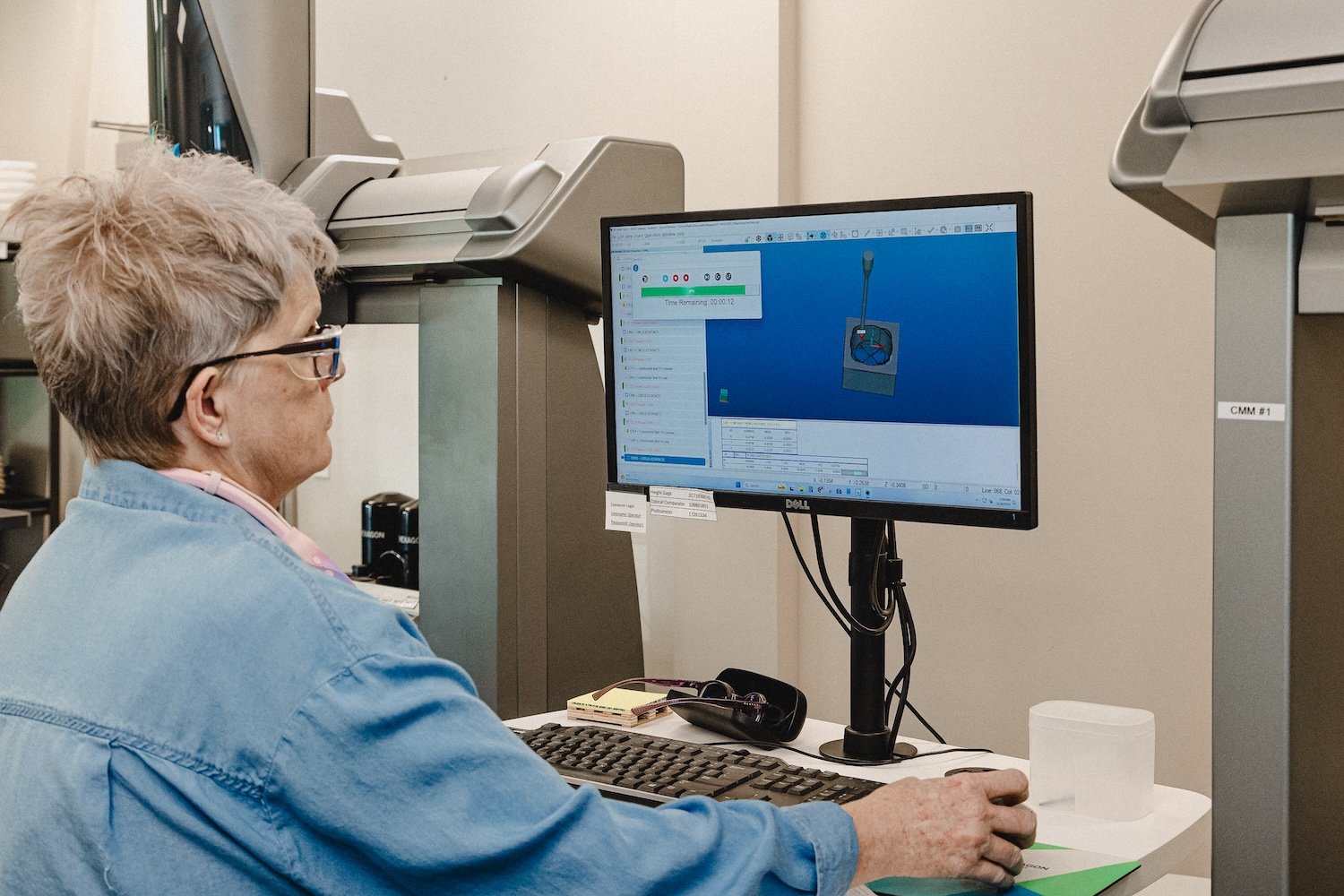

Our commitment to precision is further strengthened by ProShop ERP, a robust management system at every station that allows us to track and optimize every step in real-time. Using CMM inspection technology, we verify that every part meets tight tolerances before it leaves our facility. This focus on quality at every level means you can trust TORQ to deliver parts that consistently perform under real-world demands.

Steps We Take to Ensure Quality

1

Our Review Requirements

Quality starts with understanding exactly what our customers need. At TORQ, we begin every project with a detailed review of your requirements, ensuring we fully understand your specifications, goals, and challenges. This collaborative step allows us to align our process with your expectations and identify the best solutions to meet your unique needs—because getting it right from the start sets the stage for success.

2

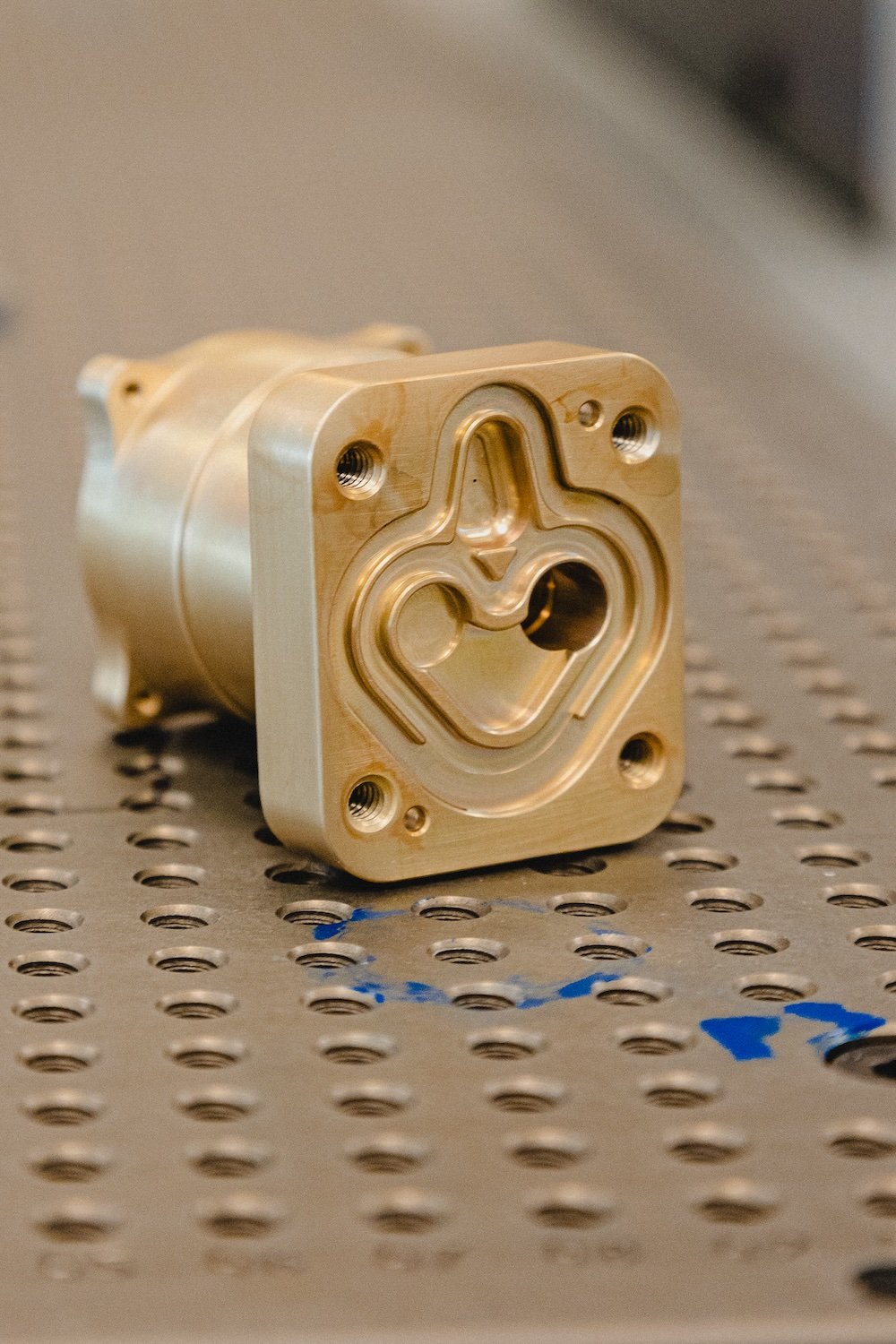

Quality & Process Planning

Once the requirements are clear, our quality manager creates a tailored process plan to guide production. This plan outlines every step, from material selection to final inspection, ensuring a seamless workflow and minimal margin for error. By leveraging advanced tools like ProShop ERP and drawing on years of experience, we design a process that guarantees precision and reliability at every stage.

3

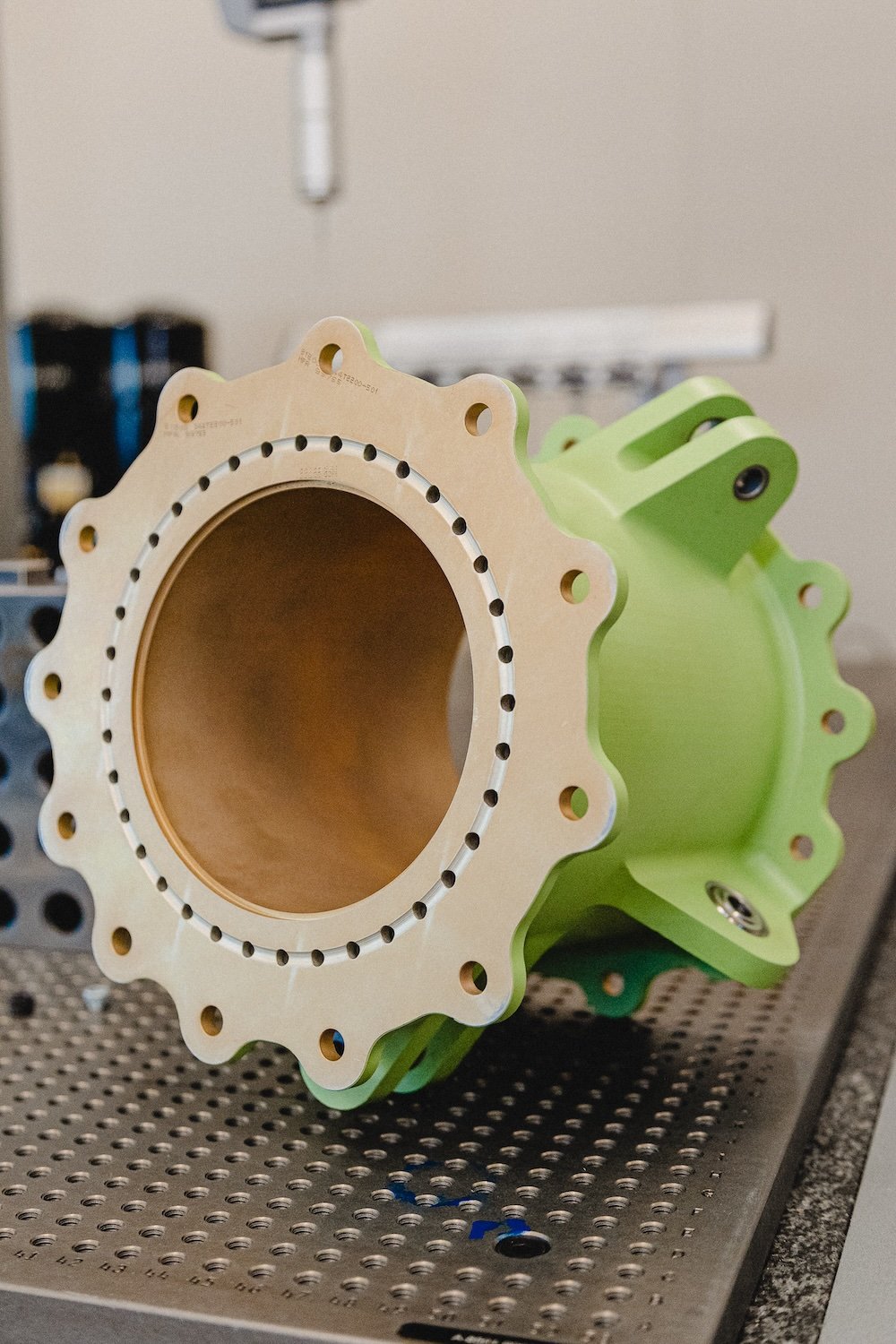

In-Process Quality Checks

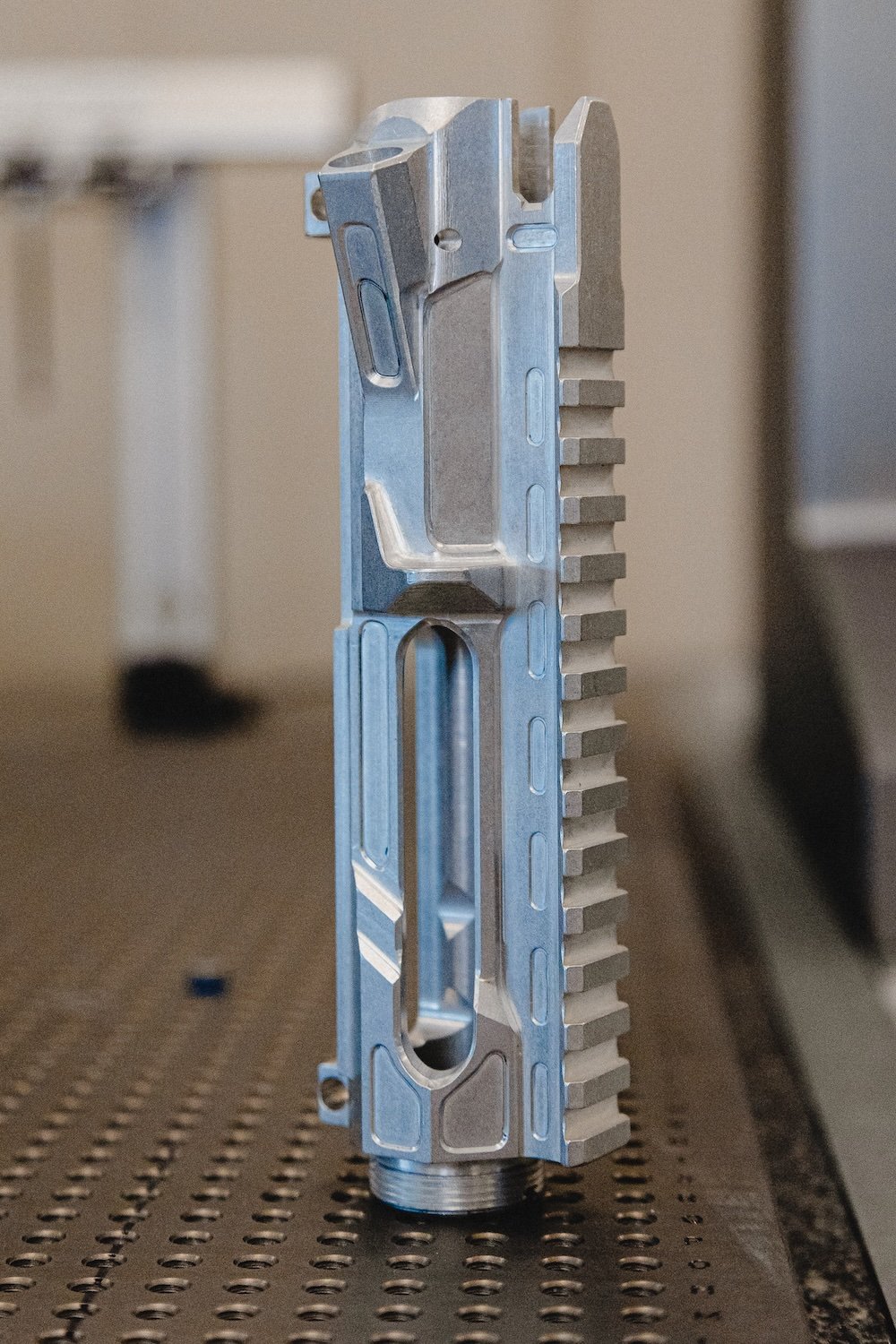

As your parts move through production, our skilled machinists conduct meticulous in-process checks to maintain strict adherence to tolerances and specifications. Using state-of-the-art equipment and their deep expertise, our team ensures that any adjustments are made immediately, reducing waste and maintaining the highest quality standards.

4

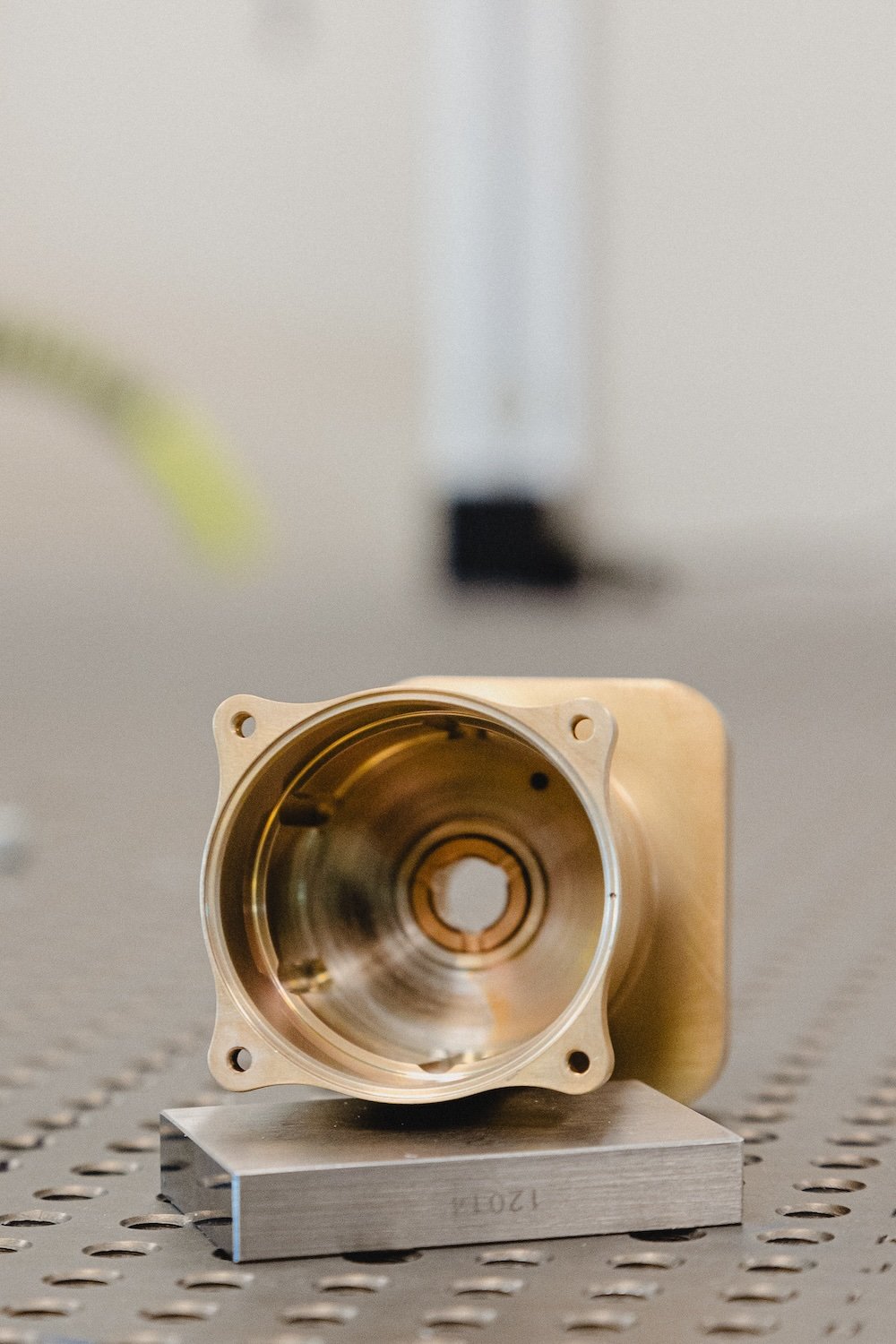

Inspection & Documentation

Before any part leaves our facility, it undergoes a rigorous final inspection by our quality team. Utilizing advanced CMM technology and calibrated tools, we verify that every dimension meets your exact requirements. We also complete all necessary documentation, including inspection reports and certifications, so you can trust that your parts meet the highest industry standards—every time.

AS9100D and ISO 9001:2015 Certified

Blue Sun Manufacturing (Formerly doing business as TORQ Manufacturing) proudly holds AS9100D with ISO 9001:2015 certification from NSF-ISR, a globally recognized standard for quality management in aerospace and other high-precision industries. This certification demonstrates our commitment to maintaining rigorous quality control processes, ensuring consistency, reliability, and excellence in every part we produce. By adhering to these stringent standards, we provide our customers with the confidence that their projects are handled with precision and professionalism at every step.